Florida's state created a home economy program in 1989 for waste management education. Today, almost two-thirds offer multidisciplinary waste administration programming. These efforts have led to more than half of a million dollars in grants for source reduction/recycling programs. These funds will be available to twenty more counties in 1990.

Cost of waste management and disposal in florida

Residents in Florida are required to pay a fee when disposing of solid waste. This fee is charged annually to single-family, multi-family, and mobile home property taxes. The rate is $173 per household per year. The waste management service provides recycling and trash collection services.

The history of the contractor responsible for trash collection in Brevard County Florida is extensive. The company has been the trash hauler in the county since 1975. It employs around 280 people in two Melbourne locations.

Recycling rate in florida

Recently, the Florida Department of Environmental Protection released its 2013 recycling report. It showed that the state's recycling rates have increased by one percent. This is significant, as the state is now recycling almost half of its total solid refuse. The state increased its recycling rate by 11.8 million tons from 9.7 Million Tons in 2012 to 11.8 Million Tons in 2013.

Alachua County possessed the highest recycling rate of any county in Florida in 2011, at 50 percent. This record was set for the second year in a row by Alachua County, which recycled 50% of its MSW. Alachua County recycled about 200,000 tons of trash in that same year.

Management of medical refuse in florida

Florida has strict regulations for medical waste management. Proper segregation, transport, and storage methods are vital to ensure the safe disposal of biomedical waste. Florida law defines biomedical trash as any kind of solid or liquid waste which could cause infection to the human body. It includes sharps, body fluids, IV bags, non-liquid tissues, and bodily fluids.

The EPA imposed strict emission limits for medical waste incinerators in 1997. These standards have contributed to a decrease of HMIWIs. However, the EPA continues to monitor medical waste incinerator standards. The goal is to make it easier for medical facilities and medical offices to dispose of biomedical waste in an environmentally responsible manner.

Public forums and seminars about waste management in florida

Waste management experts in Florida use a range of methods to ensure that waste management is as sustainable and efficient as possible. These methods include recycling, source reduction, proper handling of household hazardous materials, and proper disposal. Waste management experts provide education and training to the public through seminars and forums. They work closely with business and academic partners to find solutions for waste management.

These events are often focused on envisioning the future. The Environmental Symposium is a joint event hosted by the Environmental Protection Board and University of North Florida Institute of Environmental Research and Education in Jacksonville. It brings together community leaders and officials as well as innovators and utilities to promote environmental collaboration. The program is broken down into breakout sessions that allow participants to address specific concerns.

FAQ

What is Kaizen, exactly?

Kaizen, a Japanese term that means "continuous improvement," is a philosophy that encourages employees and other workers to continuously improve their work environment.

Kaizen is founded on the belief of everyone being able to do their job well.

What do we mean when we say "project management"?

We mean managing the activities involved in carrying out a project.

These include planning the scope and identifying the needs, creating the budget, organizing the team, scheduling the work and monitoring progress. Finally, we close down the project.

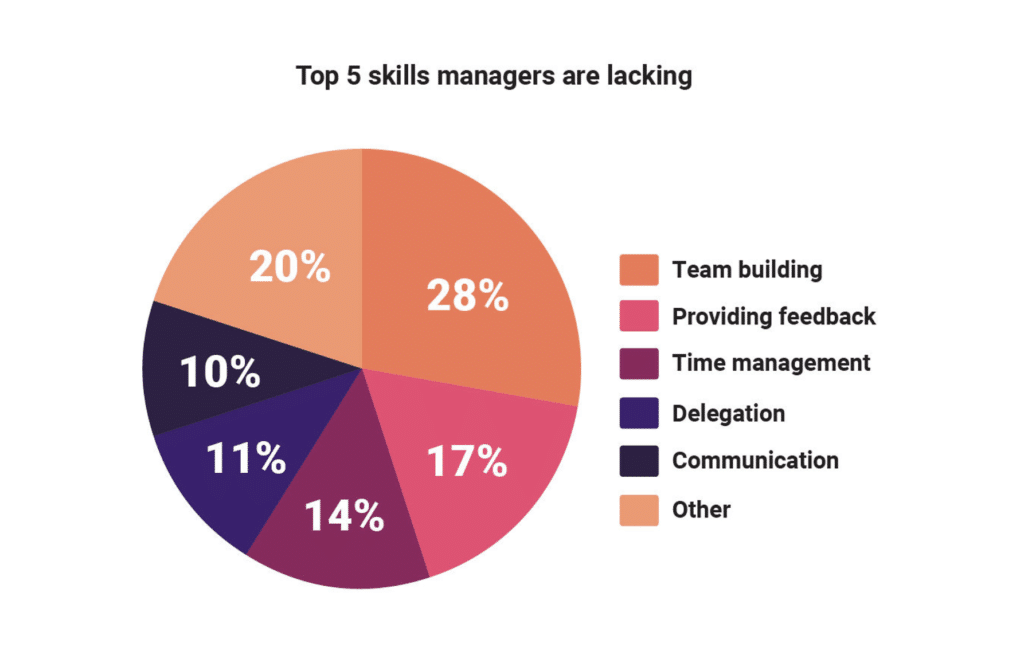

What are the most important management skills?

No matter if they are running a local business or an international one, management skills are vital. These skills include the ability manage people, finances and resources as well as other factors.

When you need to manage people, set goals, lead teams, motivate them, solve problems, develop policies and procedures and manage change, management skills are essential.

As you can see, there's no end to the list of managerial duties!

Statistics

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- As of 2020, personal bankers or tellers make an average of $32,620 per year, according to the BLS. (wgu.edu)

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

External Links

How To

What is Lean Manufacturing?

Lean Manufacturing methods are used to reduce waste through structured processes. They were developed by Toyota Motor Corporation in Japan during the 1980s. The primary goal was to make products with lower costs and maintain high quality. Lean manufacturing eliminates unnecessary steps and activities from a production process. It is made up of five elements: continuous improvement, continuous improvement, just in-time, continuous change, and 5S. Pull systems are able to produce exactly what the customer requires without extra work. Continuous improvement refers to continuously improving existing processes. Just-in-time is when components and other materials are delivered at their destination in a timely manner. Kaizen refers to continuous improvement. It is achieved through small changes that are made continuously. Last but not least, 5S is for sort. To achieve the best results, these five elements must be used together.

Lean Production System

The lean production system is based on six key concepts:

-

Flow - focus on moving material and information as close to customers as possible;

-

Value stream mapping - break down each stage of a process into discrete tasks and create a flowchart of the entire process;

-

Five S's - Sort, Set In Order, Shine, Standardize, and Sustain;

-

Kanban – visual signals like colored tape, stickers or other visual cues are used to keep track inventory.

-

Theory of constraints - identify bottlenecks during the process and eliminate them with lean tools like Kanban boards.

-

Just-in-time delivery - Deliver components and materials right to your point of use.

-

Continuous improvement is making incremental improvements to your process, rather than trying to overhaul it all at once.