You can use a continuous improvement method to get the desired results over time. This type of methodology is a series of iterative steps over many design generations. It is also known as Lean Six Sigma. This article will focus on one variant of the PDSA technique based upon SIPOC analysis. The application of the PDSA technique is explained in the context a engineering design studio.

Lean Six Sigma

Lean Six Sigma (or Continuous Improvement) is a methodology that helps to make processes simpler and more predictable. Simpler processes result in fewer errors, thus lowering the risk of process failures. The method uses statistical process control methods (SPC) to improve process performance and control variables. This methodology can be applied to any product or service. The company must establish clear measurable characteristics and use data to guide the changes.

PDSA

The PDSA continuous improvements methodology employs a continuous loop of process analysis, design, and action to improve a business's process. The study step in PDSA's initial phase is where the team evaluates and compares the results of an experiment. This step allows the team to determine if the improvement was a success. This step allows the team to perform analysis using control charts, which can be used to identify expected and special causes of variation.

Variation of PDSA

PDSA (Personal Development and Support) is a method of continuous improvement and problem-solving, with a clearly defined focus and measurable targets. The process starts with a careful planning stage, and then moves on to effective action. Next, each idea must be tested and evaluated for feasibility and viability. By measuring the outcomes, the project team ensures that any change will lead to improvements that will last.

PDSA based SIPOC analysis

SIPOC analysis is an effective tool for improving business processes. It's an easy way to categorize data into five categories. SIPOC diagrams provide an overview of all the processes and help teams to understand them better. They are also a great way to focus discussions.

PDSA based DMAIC

Continuous improvement methodologies that follow the DMAIC process are useful for organizations seeking to improve their processes. These methods are easy to follow and are structured so that organizations can understand and eliminate inefficient processes. Additionally, they help them achieve measurable results. These tools can help organizations track which changes have the most impact and which ones are not. They can also have a difficult time implementing effective controls.

PDSA based off kanban boards

Kanban boards have many advantages. For example, they allow you to visualize work in progress, assign tasks to different team members, and include attachments or images for each task. They allow you to manage how much work you have completed and when it is complete.

Kaizen is based on SIPOC analysis

The SIPOC structure is a powerful tool for improving process performance. It helps define the boundaries of a process, gather relevant information and present it in a clear and easily understandable manner. It is useful for identifying process variations that could affect key performance indicators (KVIPs), and it is particularly helpful in the Define phase. It is also useful for teams and other stakeholders to plan improvements to improve processes.

PDSA based on PDSA variation

PDSA, a continuous improvement approach, is based on the principle that actual and anticipated results can be compared. The PDSA process compares the actual results to the planned results. Finally, the plan and reality are compared. The team then analyses the data to determine if there were any measurable improvements. This data is often categorized using a control chart, to help distinguish between expected variation and special cause variation.

FAQ

What is Six Sigma?

It's an approach to quality improvement that emphasizes customer service and continuous learning. This is an approach to quality improvement that uses statistical techniques to eliminate defects.

Motorola invented Six Sigma in 1986 as part its efforts to improve manufacturing.

The idea spread quickly throughout the industry, and today, many organizations are using six sigma methods to improve product design, production, delivery, and customer service.

Six Sigma is so popular.

Six Sigma is easy to use and can lead to significant improvements. Six Sigma also gives companies a framework for measuring improvement and helps them focus on what is most important.

What are the three main management styles you can use?

These are the three most common management styles: participative (authoritarian), laissez-faire (leavez-faire), and authoritarian. Each style has strengths and flaws. Which style do you prefer? Why?

Authority - The leader is the one who sets the direction and expects everyone in the organization to follow it. This style works best in large organizations that are stable and well-organized.

Laissez-faire – The leader gives each individual the freedom to make decisions for themselves. This style works best when an organization is small and dynamic.

Participative - The leader listens to ideas and suggestions from everyone. This approach works best in small organizations where everyone feels valued.

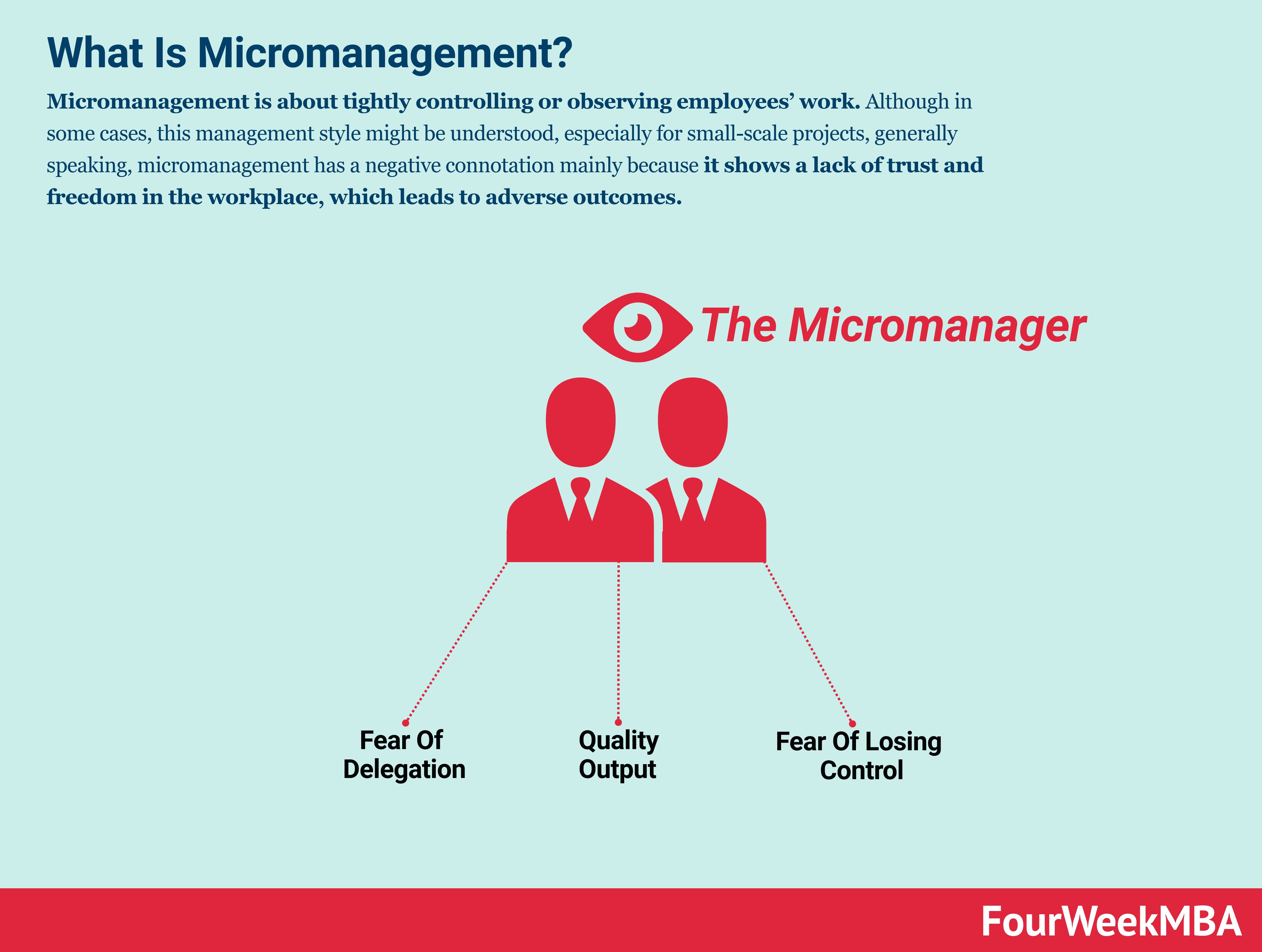

What are the most common errors made by managers?

Managers can make their jobs more difficult than necessary.

They might not give enough support and delegate the right responsibilities to their staff.

A majority of managers lack the communication skills needed to motivate their team and lead them.

Managers set unrealistic expectations and make it difficult for their team.

Some managers may try to solve every problem themselves instead of delegating responsibility to others.

Statistics

- Our program is 100% engineered for your success. (online.uc.edu)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

External Links

How To

How do you apply the Kaizen method to your life?

Kaizen means continuous improvement. This term was first used by Toyota Motor Corporation in the 1950s. It refers to the Japanese philosophy that emphasizes continuous improvement through small incremental changes. It's a process where people work together to improve their processes continuously.

Kaizen is one of the most effective methods used in Lean Manufacturing. The concept involves employees responsible for manufacturing identifying problems and trying to fix them before they become serious issues. This is how you can improve the quality and lower the cost.

The main idea behind kaizen is to make every worker aware of what happens around him/her. It is important to correct any problems immediately if they are discovered. If someone spots a problem while at work, they should immediately report it to their manager.

Kaizen is based on a few principles. Start with the end product, and then move to the beginning. If we want to improve our factory for example, we start by fixing the machines that make the final product. We then fix the machines producing components, and the machines producing raw materials. Finally, we repair the workers who are directly involved with these machines.

This method is known as kaizen because it focuses upon improving every aspect of the process step by step. Once the factory is fixed, we return to the original site and work our way back until we get there.

Before you can implement kaizen into your business, it is necessary to learn how to measure its effectiveness. There are several ways that you can tell if your kaizen system is working. One of these ways is to check the number of defects found on the finished products. Another method is to determine how much productivity has improved since the implementation of kaizen.

Another way to know whether kaizen is working is to ask yourself why did you decide to implement kaizen. Was it just because it was the law or because you wanted to save money? Did you really believe it would lead to success?

Congratulations! You're now ready to get started with kaizen.